|

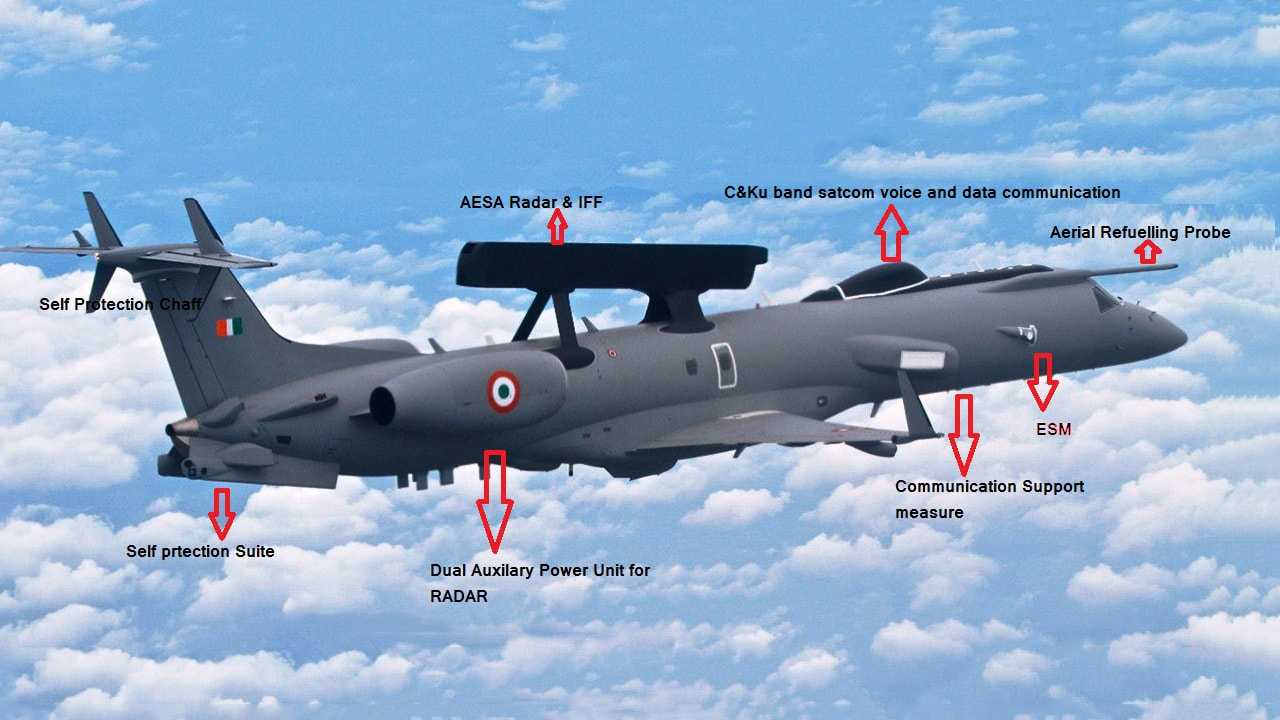

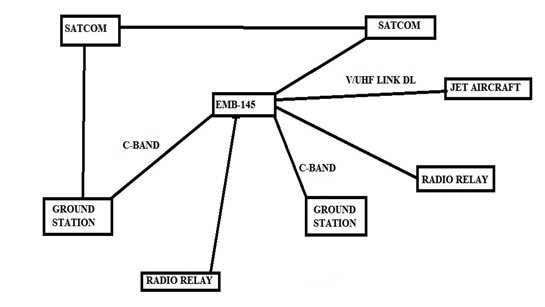

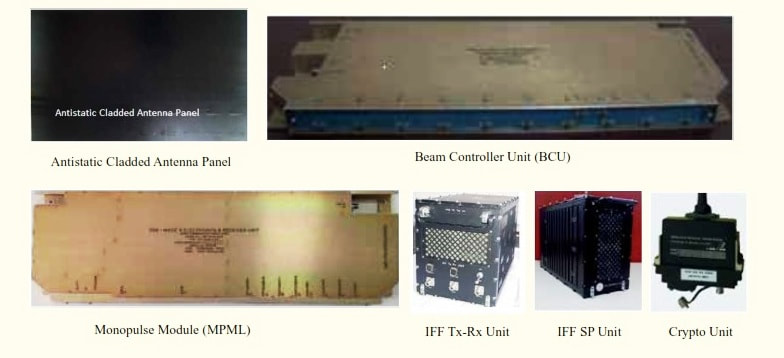

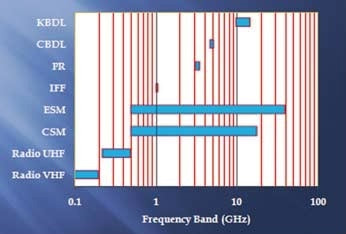

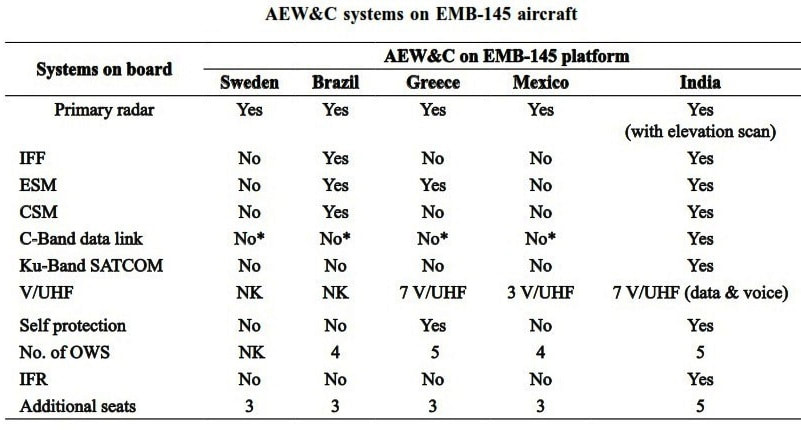

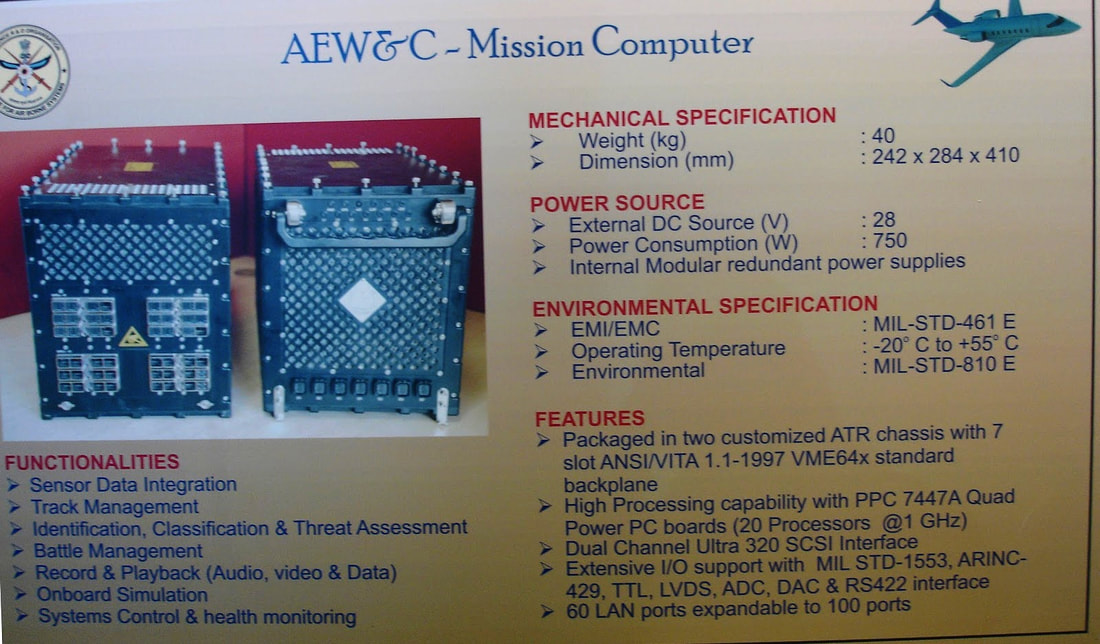

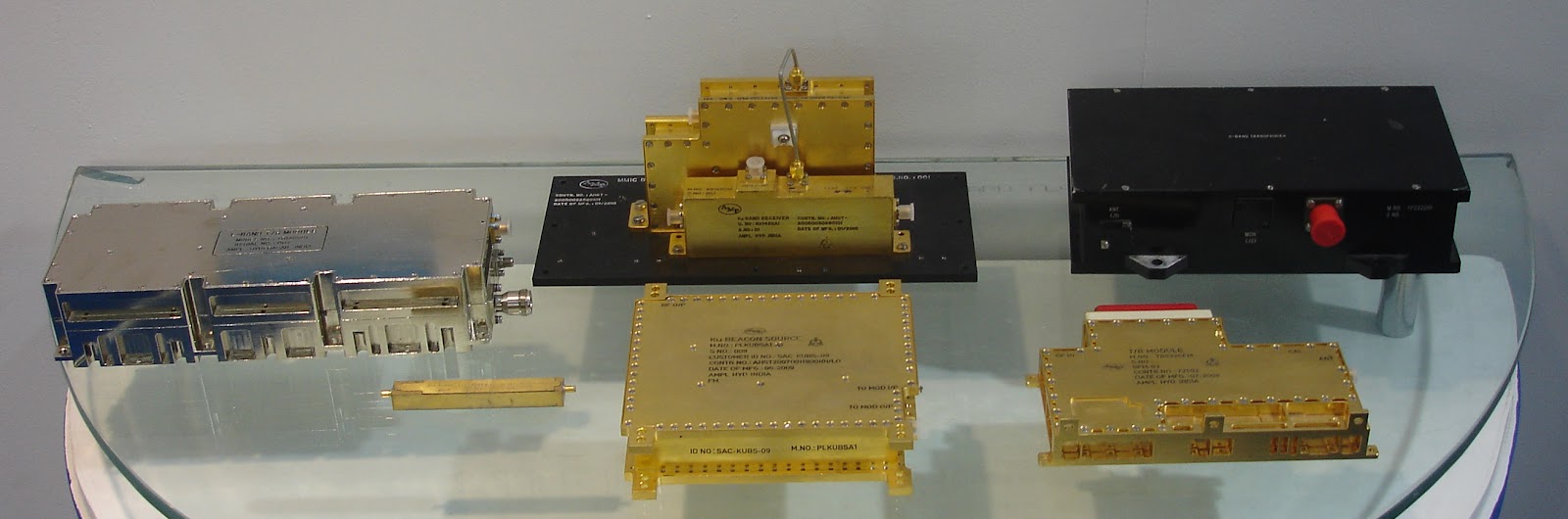

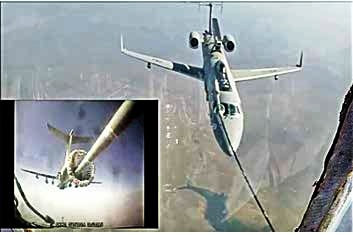

What is AEW&C? AEW&C system is a potent force multiplier, providing surveillance, tracking, identification and classification of the Airborne/Sea surface targets. The information from multiple sensors are collated, associated and fused to provide a cogent and comprehensive air situation picture on configurable consoles. Further capabilities include threat assessment and enabling the interception of the hostile targets through guidance of own interceptor. Introduction The development of an indigenous Airborne Early Warning and Control System (AEW&C) was taken up by DRDO & IAF in 2004. Development of indigenous AEW&C system as a mission mode programme commenced with appropriating Centre for Airborne Systems (CABS), Bengaluru, as the nodal agency. The development was taken up based on operational requirements evolved jointly by a team of DRDO and IAF. The platform for the development was specified by the IAF as EMB-145 executive jet manufactured by M/s Embraer of Brazil. After the sanction of the programme, IAF revised the operational requirements in tune with their emerging war fighting scenario. The revised operational requirement necessitated building of an AEW&C system on a small aircraft with all the systems and functionalities similar to that of the bigger AWACS being procured by IAF. DRDO took up the challenge and has made the systems a reality. The AEW&C aircraft is a derivative of Embraer ERJ-145 extensively modified and customized to house the indigenous mission systems developed in India. The complete integration of the mission system and its flight evaluation has been carried out in India. One of the main features of the aircraft is that it is the Embraer executive jet aircraft to have air to air refueling. The system was envisaged to have full net centric capability through multiple LOS and Satellite Communication Data links, on-board Mission Computer, which enables the operator to carry out the information fusion, mission control, and reconfigurable operator consoles for the operator to interact with the system and exploit the system capabilities in tune with the operational environment. The AEW&C system is a system of systems having primary radar (PR), secondary surveillance radar (SSR), electronic support measure, communication support measure (CSM), ‘C’- Band Data Link (CBDL), ‘Ku’- Band SATCOM data link (KBDL), V/UHF communication link working in the microwave region. These subsystems are mounted onboard an EMB 145 aircraft, the Indian AEW&C system is versatile in choice of the sub-systems and its capabilities. Equipment's

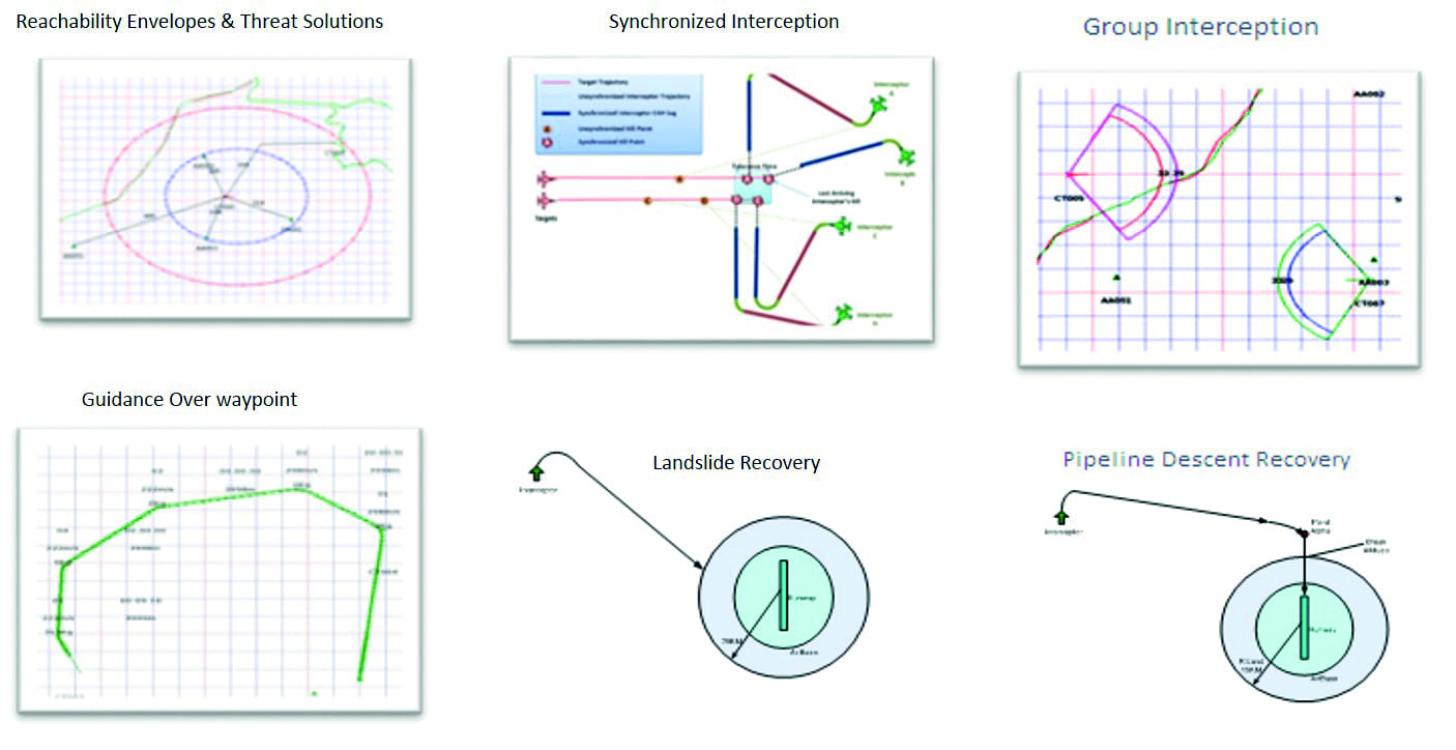

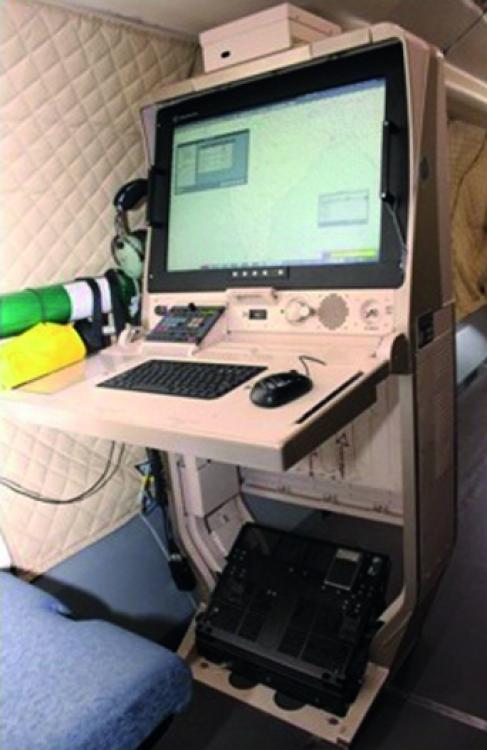

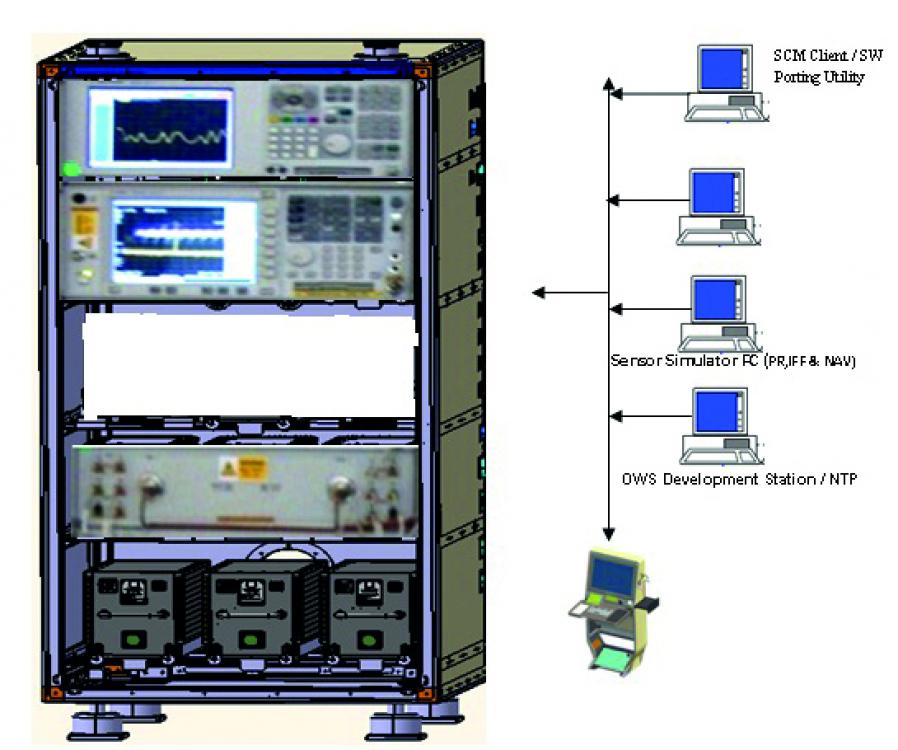

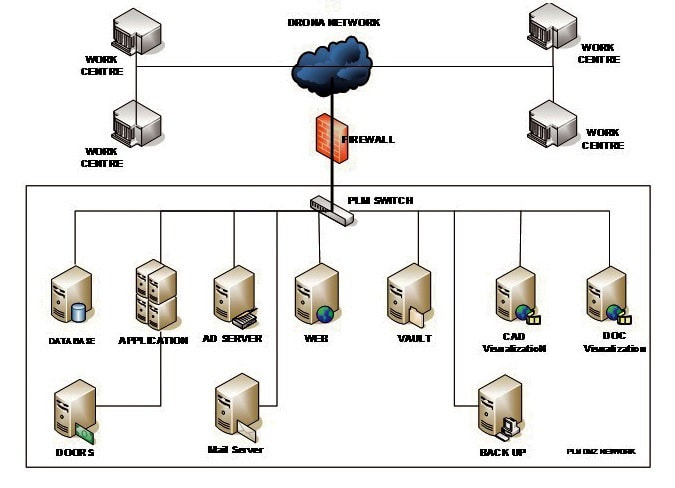

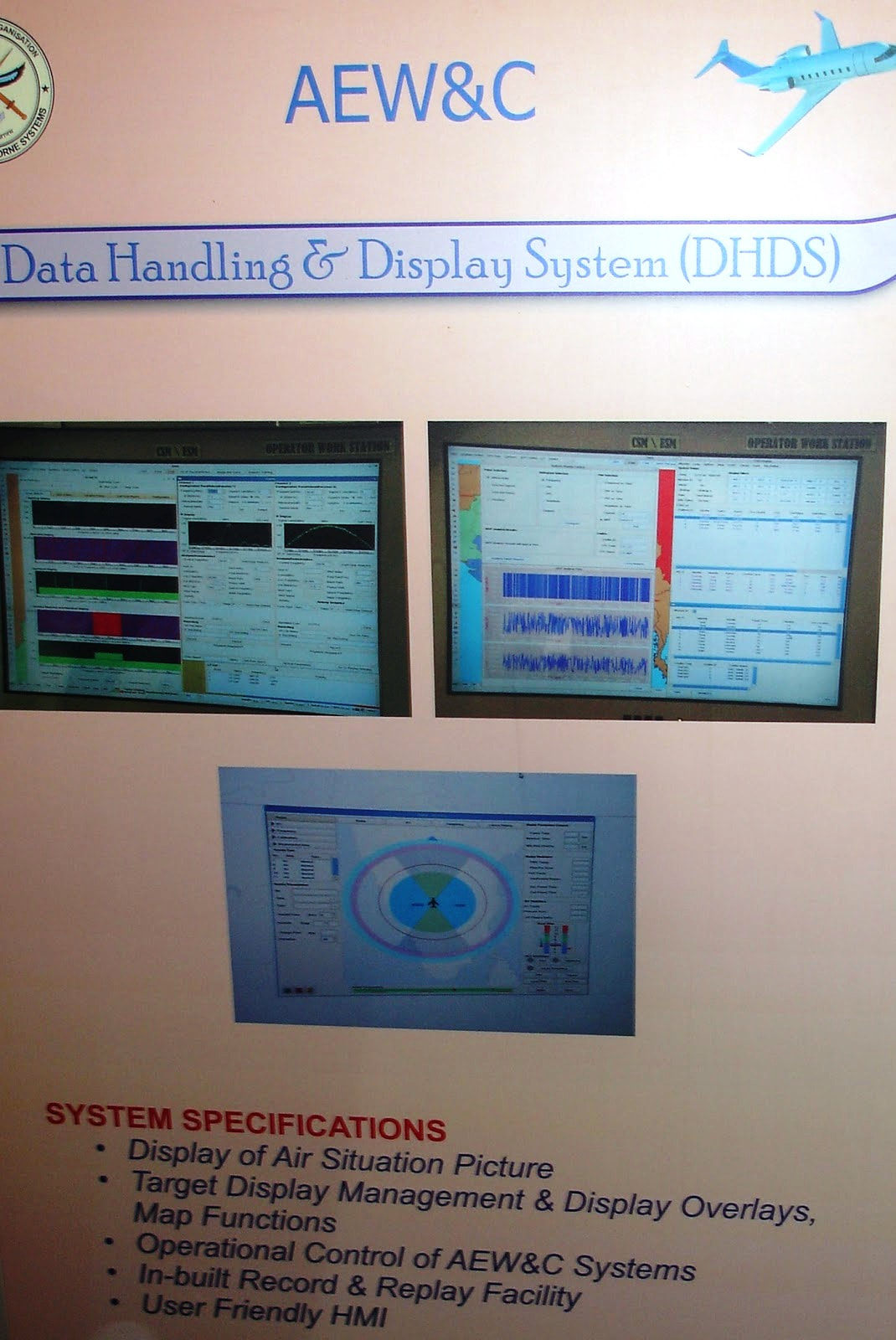

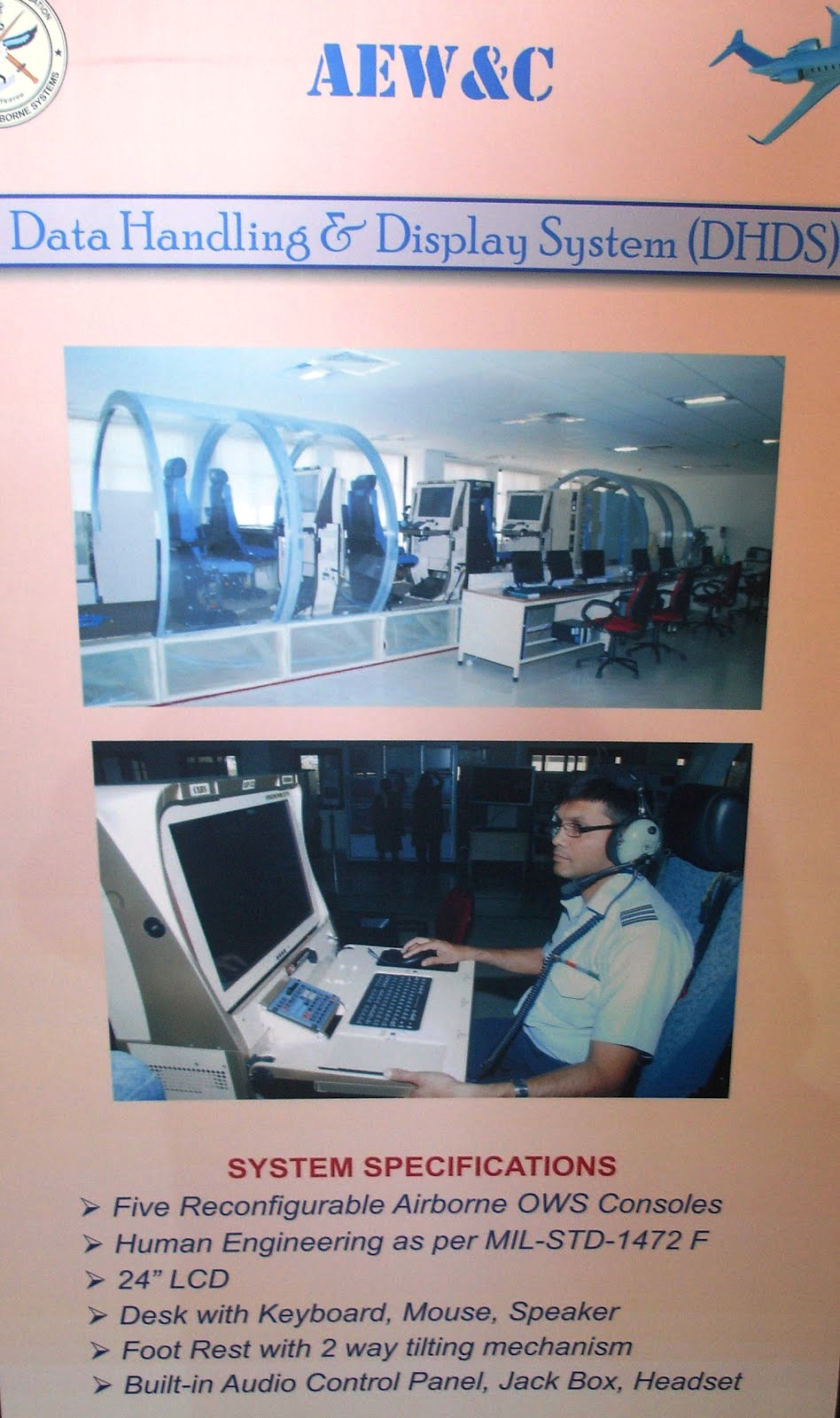

All the above systems are electrically and functionally integrated through a high speed LAN and complete suite of tactical software fully developed in house. This software provides functionalities such as multi sensor tracking and data fusion, multi target tracking, identification and classification, system control and monitoring interception and battle management functions, all of which are developed in house. A comprehensive Human Machine Interface again developed in house, projects the real-time air situation picture, into five reconfigurable consoles, in a manner required by the individual operators. In addition to the airborne complement, five major ground systems supporting all aspects of planning, training, maintenance, and integration with IAF Command and Control Centre also have been developed fully indigenously. These are:

All of these are backed by a regular post development support project taken by CABS to enable operational and maintenance support to the IAF for a period of three years. The AEW&C system has undergone extensive flight evaluation flying close to 1500 hrs (700+ sorties). These include flying at Bengaluru, evaluation campaigns at various IAF bases such as Jamnagar, Bhatinda, Jodhpur, Gwalior, Agra, Chabua to state a few. Evaluation of the system also includes evaluation through conduct of Large Fleet Engagement exercise (more than 25 of them) to evaluate the complete performance capabilities of the AEW&C command, control, battle management, etc. The AEW&C system is being integrated with the IAF’s Command and Control System. Specifications Range: 250-300km Aircraft range: 3700km Service ceiling: 3700ft Maximum speed: Mach 0.8 Sensor arrangement In AEW&C, the real estate available on board the aircraft is limited and hence antennae are to be kept in close proximity to each other. On the exterior of the AEW&C aircraft, there are 89 antennae and sensors located in a cramped condition. In addition, aircraft body being metallic, the individual antenna radiation pattern gets distorted due to ‘body effect’. Hence, prior knowledge of the individual antenna radiation pattern alone cannot help while selecting suitable locations on the exterior of the aircraft for various antennae. Moreover, aircraft safety being of the highest priority, the ideal location requirement from antenna radiation pattern point of view has to take a back seat. The first step toward location identification is to predict the antenna radiation pattern with ‘body effects’. For this, one has to resort to any of the computational electro-magnetic methods. Commercial tools such as E-Mind have been used for this. This exercise is recitative and time consuming. Depending upon the number of locations tried for each antenna, one generates voluminous data. In general the antenna location process went through the following steps:

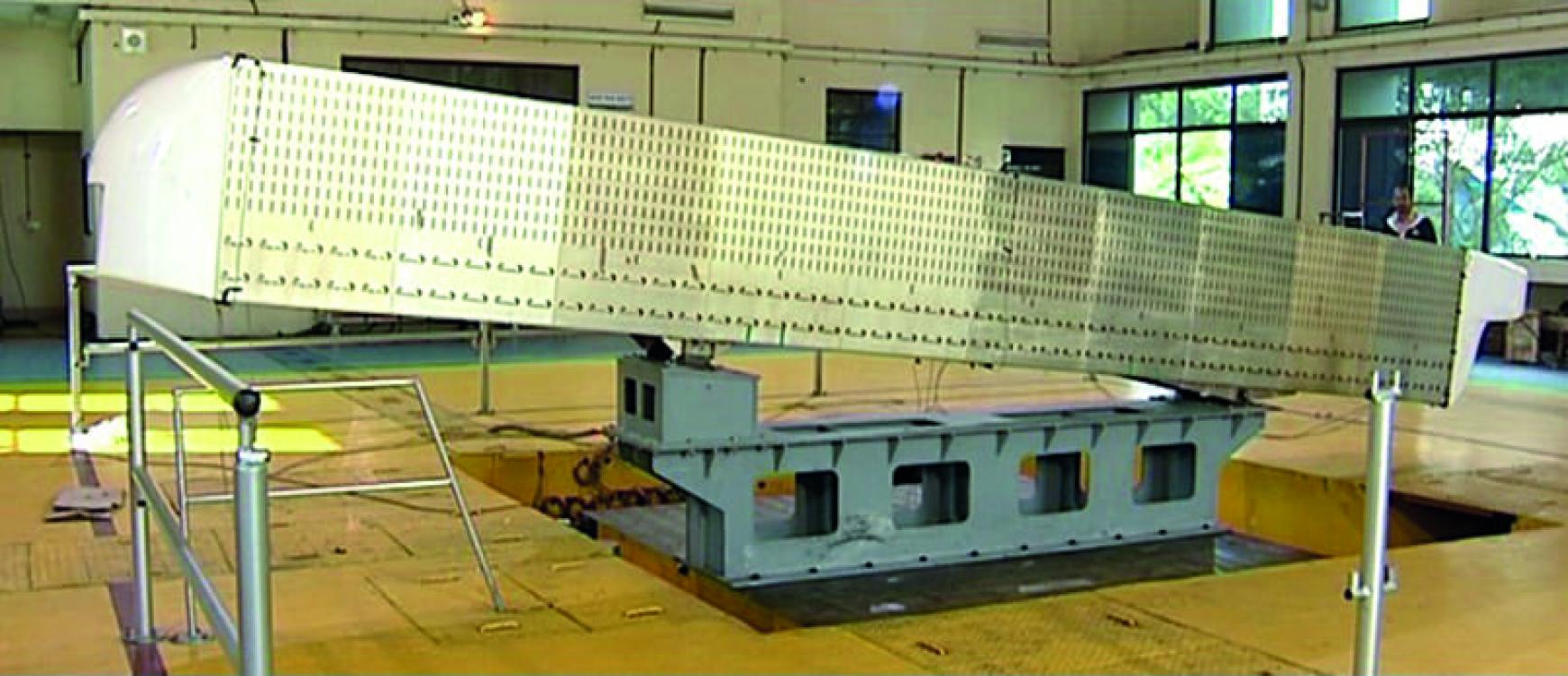

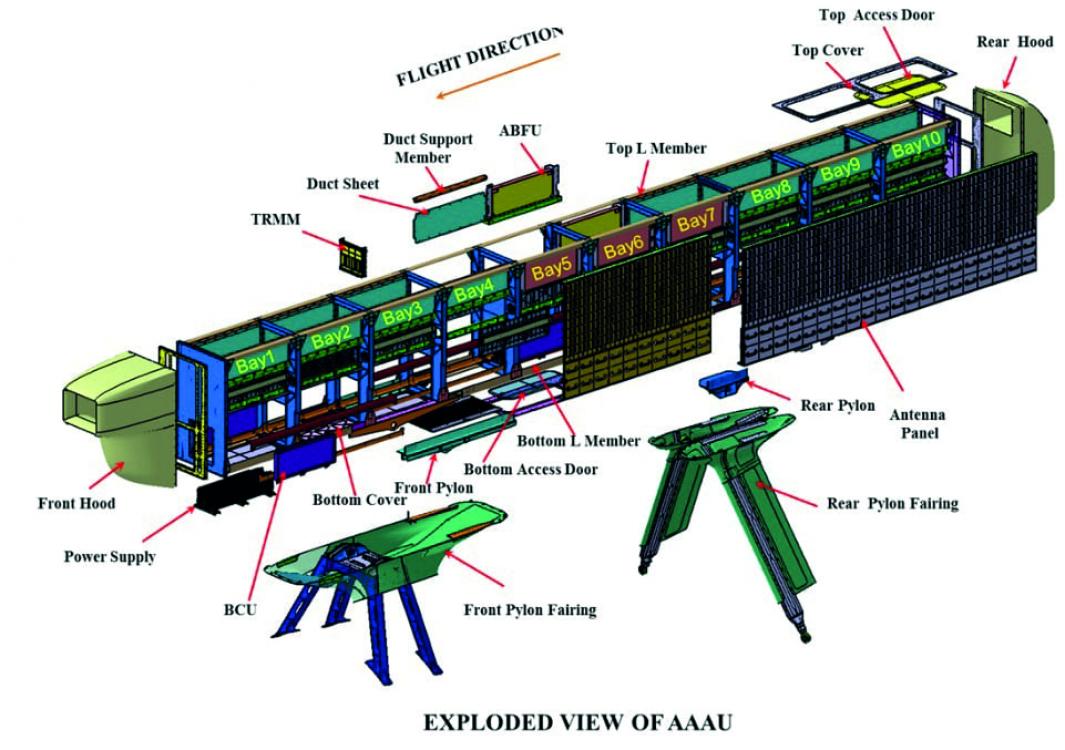

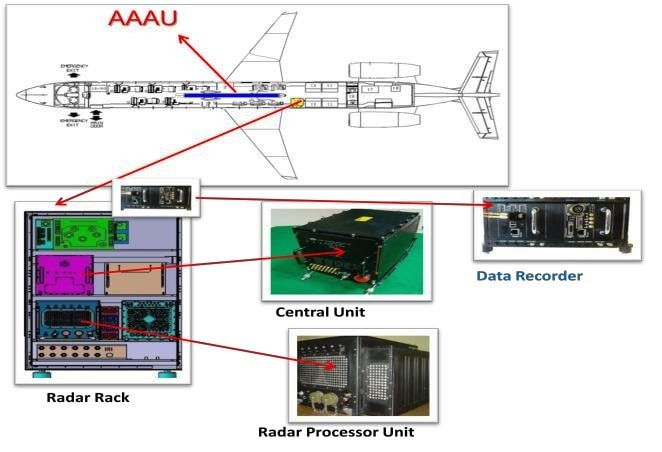

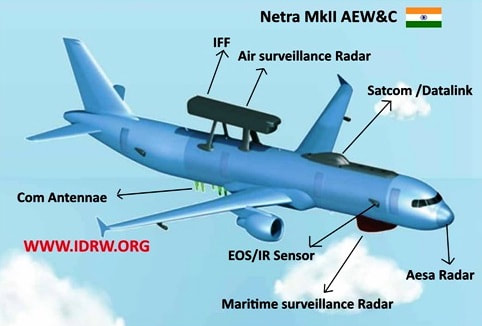

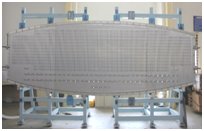

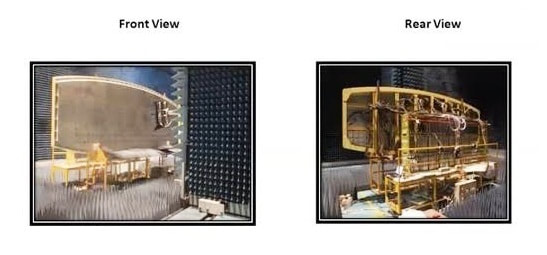

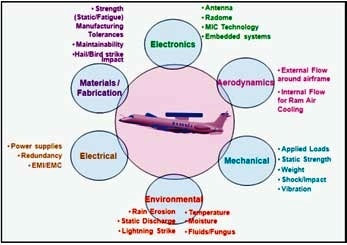

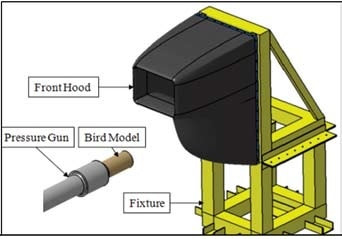

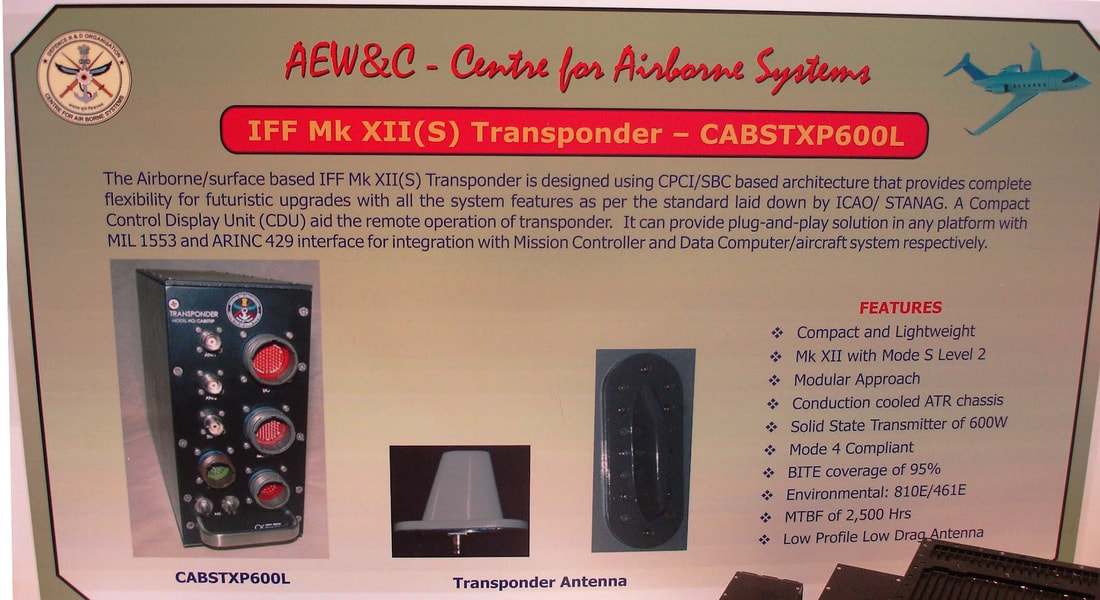

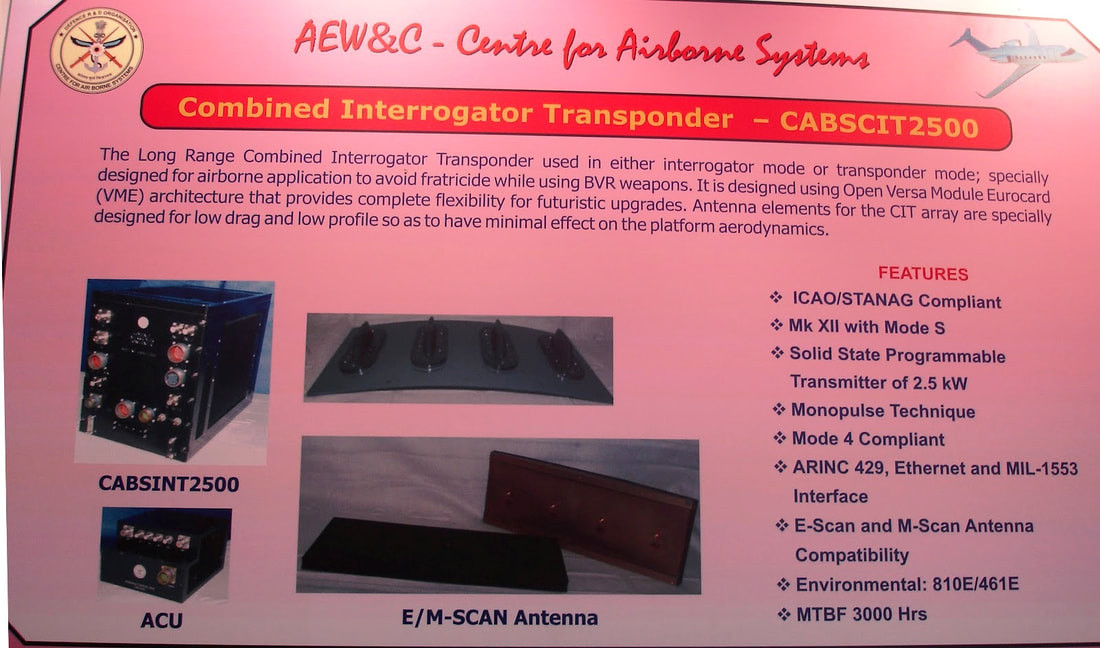

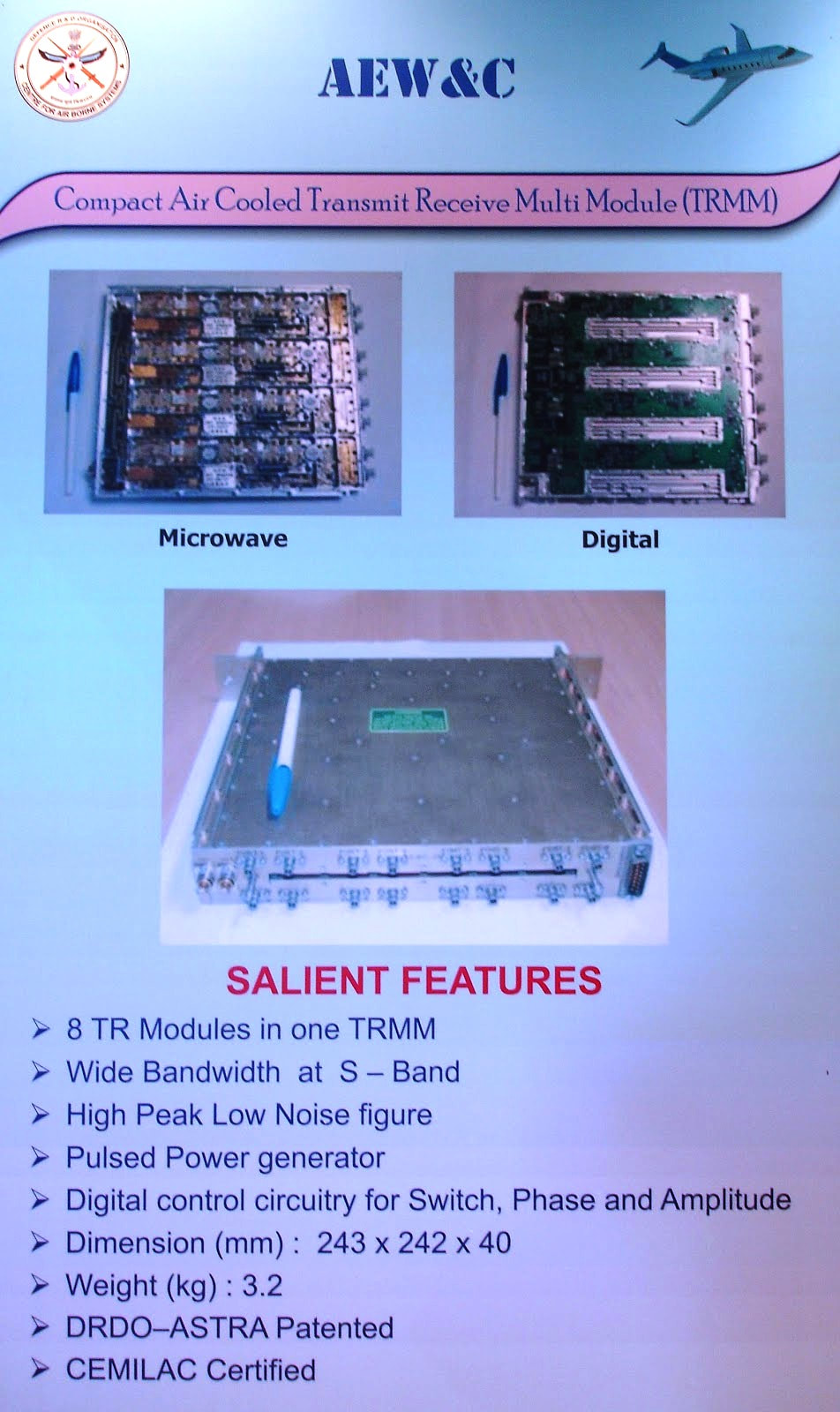

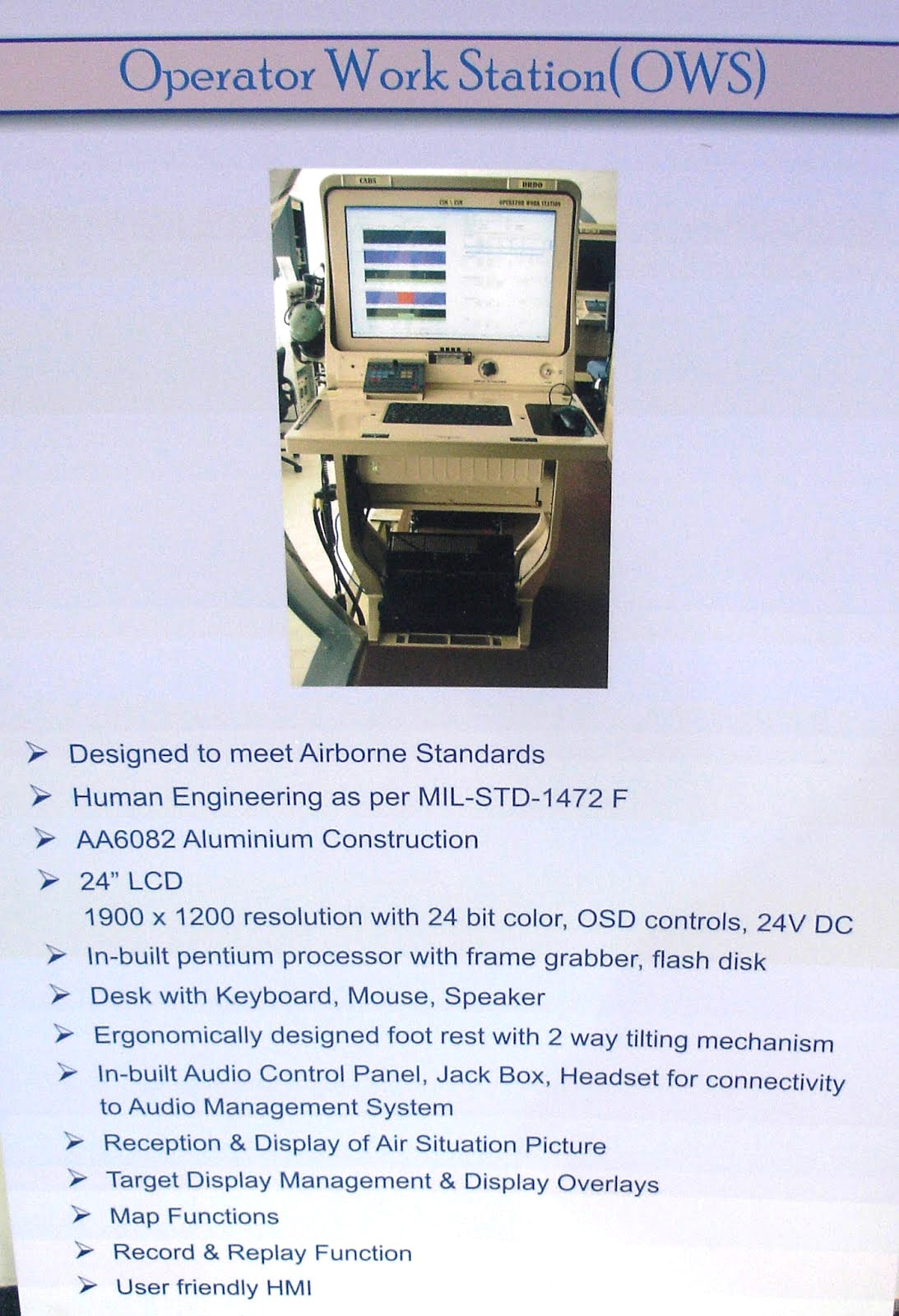

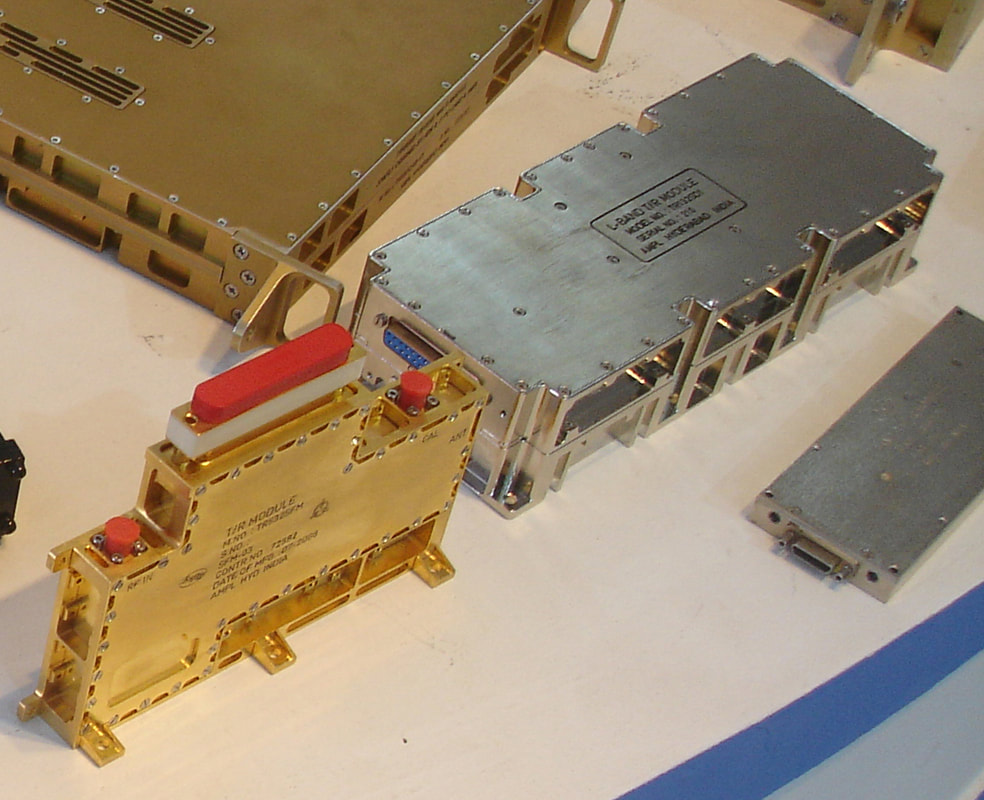

The location of the SATCOM radome adjusted forward to allow sufficient air for the active antenna array unit located in the rear under all ‘angle-of-attack’ conditions. Similarly, the AAAU itself was moved forward to avoid damage from a possible broken engine blade leading to a flight hazard. Additional fins had to be added to stabilize the aircraft under ‘side-slip’ conditions as there was a blockage of air to the control surface. Active electronically scanned array radar Active Antenna Array Unit (AAAU) is a major as well as critical component of the AEW&C system and has been indigenously developed state-of-the-art technology. AAAU is an active electronically scanned array (AESA)-based radar having more than 1,000 elements producing several tens of kilo watts of power. The AAAU is mounted on dorsal side of the aircraft fuselage using four pylons. Being an external structure of an aircraft with the dimensions of 8.2m X 0.9m X 0.5m, it qualified stringent airworthiness requirements. AAAU structure is designed for aerodynamic loads, inertia loads and aero-elastic requirements. The mechanical design of AAAU is designed considering easy accessibility for various electronic components (LRUs) inside the AAAU. The fool proof design of AAAU caters for antenna structure, thermal, microwave electronics & digital electronics. Wind tunnel tests and CFD studies were conducted for the AAAU to optimize the aerodynamic shape of front and rear hood and to estimate the internal and external aerodynamic loads. Structural tests such as Modal Analysis Test (MAT), Static Strength Test (SST) and Ground Vibration Test (GVT) were conducted and validated with Finite Element Analysis. Internal design is made to optimize the cable routing, for accommodation of front end electronics of primary & secondary surveillance radars and cooling of them. This design, using ram air for cooling the electronics inside the AAAU, drastically reduces the burden on the cooling system virtually to one third and consequently the power that is required for cooling is also reduced. The front hood and antenna panels were structurally optimized, tested and certified for bird impact requirements specified in Federal Aviation Regulation (FAR– 25). The radar offers multifunction, multi-mode capability with highly agile beam steering and electronic beam stabilization by the array. Radiating interface, the major subsystem of the PR Active Electronically Scanned Array (AESA), is first of its kind. To obtain higher sensitivity, the AAAU is designed with high power transmit capability and also achieved ultra-low side lobe level in the receive mode. The AAAU array has been developed with amalgamation of analog and digital electronics, microwave & electrical technologies. Its sophisticated electrical power distribution system comprises enough safety measures. The performance of the array is maintained by in-situ calibration system. Critical building block that supports all functional requirements of the radar and serves as heart of the AAAU system are TRMMs. The TRMM’s also have RF and digital manifolds to accommodate the size and weight due to its unique design. The unique design of integrated antenna aperture for both primary and secondary surveillance system along with cladded radome has reduced the weight and volume constraints. This uniqueness has also helped in bringing out the microwave losses thus making it a win-win from both structural and electronics aspects. With the aid of several stages of RF distributer and combiner networks single RF signal input is fed to all elements of planar array. The received signals from all elements are combined by TR modules and stages of RF combiners. To achieve the command & control of installed LRU’s of AAAU system a controller has been devised with required hardware and software. The unit accepts the control and commands information from central unit/IFF SP/MSC through specific interfaces and distributes the same to AAAU LRU’s. The bottom portion of the AAAU contains the Multi-output power supplies (MOPS) that require more cooling than the TR modules that are placed in the middle. The internal airflow for each of the 160 Transmit-receive multi-modules (TRMM) should be not less than 15 CFM even under blockage conditions due to the presence of SATCOM radome under all pitch- and yaw-conditions. To assess the required quantum of airflow, wind tunnel tests were carried out apart from CFD analysis. The system has about 2 km length of RF cables in the air passage. Safety against bird strikes is another vital requirement for AAAU being a large airborne antenna system. This calls for selection of proper material and structural design for the AAAU. The criteria are such that after the bird strike, there should not be a cause for any flight-safety concern. The debris from a damaged antenna beyond a certain size, for example, should not be able to enter the engine. The carbon composite front hood with aluminum mesh and the aluminum slotted array are designed for such a criterion. Apart from transient analysis, actual test is also conducted with frozen bird of 4-pound weight. Another special requirement for the airborne antenna is that it has to pass the lightning test for both direct and indirect effects. After zonal analysis, the lightning attachment points are identified and provided with paths for lightning to pass through without causing any structural damage. The indirect effects can be equally damaging like direct effects on items like the TRMM with sensitive electronics. The lightning must be discharged as much as possible by limiting the current flow in the skin. The waveguide slot array is best suited for this environment. Similarly, the SATCOM radome in the lightning prone zone has button/strip type lightning conductors to retard the lightning effect. Being external to the fuselage, the cross section of the AAAU perpendicular to the aircraft flight path should be minimal to have low additional drag. Hence, a low drag design was done by suitably designing the antenna panels as integral structural parts of the AAAU and eliminating the need for an additional protective radome. This has not only reduced the drag but also the total weight of the AAAU. After analysis, four antenna panels were joined to form a lager single panel to enhance torsional rigidity. FEM analysis was carried out on and found to be meeting the FAR-25 requirements. The most critical technology element for the radar is the Transmit-receive multi-module (TRMM). Design of the TRMM was carried out in the microwave lab and evaluated in detail. The most difficult part of the design was thermal management of the components in the TRMM without giving rise to hot spots by usage of ram-air-cooling. Secondary Surveillance Radar Secondary Surveillance Radar (SSR) is another important sensor in AEW&C system used for detecting targets, identification as a friend or foe while working in tandem with Primary Radar (PR). This information is very vital in the wartime and is also useful to form database during peace time surveillance. SSR system also called Identification Friend or Foe (IFF) system in military terminology comprises of an interrogator fitted with the main radar system on airborne platform and a transponder fitted on target aircraft. It operates as per the recommendations of the International Civil Aviation Organisation (ICAO) and STANAG 4193. The interrogator transmits pulsed signal in a particular mode of interrogation in a specified direction. Aircraft fitted with compatible transponder receives the interrogation signal and replies back in the form of another coded signal to the interrogator for processing and identification. The reply provides additional target details such as height, range and azimuth, and target status like communication failure, emergency and hijack. Mode 4 is an encrypted mode of operation that enhances its capability to be secured, jam resistant and resistant to spoofing. Operation in Mode S (level 2) gives capability of selective addressing and data link capability, which are very critical in dense air traffic. Based on the requirements of the user and platform constraint, the high power airborne IFF MK XII(S) interrogator has been developed for the AEW&C programme with a range of more than 375 km using modular approach. It comprises of Electronically Scanned Antenna Array (ESAA), solid-state transmitter, dual channel monopulse receiver and signal processor. All the LRUs of IFF system have been qualified as per the MIL STD 810E/461E/704D and certified for airworthiness by DGAQA/CEMILAC, and has been thoroughly tested in System Test & Integration Rig. More than 700 user evaluations were carried out by AFPT and ASTE including Large Fleet Engagement (LFE) sorties at various places in India. Formal ATP has been carried out by the IAF task team. Two IFF systems with adequate spare have been inducted into the IAF. Operator Work Station The face of the AEW&C system through which the operators interact with the Mission Systems onboard is the Operator Work Station (OWS). CABS OWS developed in-house to provide the operator a real-time display of the integrated tactical air situation picture on a powerful and ergonomically designed HMI, which enables the operators gain a better situational awareness of the region under surveillance. There are rugged and lightweight five front facing airborne qualified operator consoles onboard. Each OWS receives tracks, plots and emitter data from radar, IFF, ESM & CSM systems via the Mission System Controller (MSC) and provides an Air Situation Picture (ASP) to the operator. The OWS has a lightweight map engine capable of rendering both vector maps and raster maps. It supports multiple projection and coordinate systems and allows the operator to select the map layers such as coast lines, roads, and towns of his choice. The data received through the sensors are presented to the operator in different formats like symbols, textual windows, histograms, spectrum display, waterfall display etc, aiding in operations. An operator deals with complex and large amounts of data and OWS provides better data organization, processing and distribution of actionable information, improving efficiency and reducing the reaction time. The OWS provides capability of initiating interception of a hostile target, reception of the interceptor guidance solutions and commands from the MSC, facility for manual correlation of radar track data with ESM/CSM emitter data. It provides operational control facilities to all the AEW&C systems through keyboard and mouse. Emergency/Warning indications are provided via onscreen messages & audio beeps. The OWS receives the health information periodically from all sub-systems, via MSC and provides a comprehensive health status display of the systems onboard. Capability to view and monitor different areas of surveillance are provided through multiple Picture-in-Picture windows. Various tools help de-clutter the workspace and manage more electronic data. The five airborne qualified operator consoles comprise a 24” rugged LCD display integrated with a chassis housing multiple Intel-based Single Board Computer (SBC). The OWS has an audio interface through a control panel that enables the operator to access all the communication channels with press of a button while simultaneously operating the display along with headset and integrated speaker. A foldable desk with a keyboard & mouse, knob-tilting arrangement for the monitor, reading area with transparent glass, light for reading during low visibility, pedal control with PTT switch are some other features of the consoles. The operator consoles are designed as per the MIL-STD1472F ergonomics. The design also considered, in consultation with the Indian Institute of Aviation Medicine, the ergonomics of operators. The seats are adjustable according to the height and can be tilted. A two level adjustable foot rest facilitates operators with different heights to carry out operations. Each of the five operator consoles are software reconfigurable to work in one of the six modes according to the role of the operator who is operating on it. The 6 modes of operation are: Air Situation Picture (ASP) / Command & Control (C2) i.e., ASP/ C2; ASP/C2 + CSM; ASP/C2 + ESM; Global Air Situation Picture (GASP) Reconstruction & Playback; Image & Voice Playback(IVPB) and Onboard Training mode. Facility is available to the operator to switch modes as per operational requirements. This allows the operator to view the information according to his requirement. The ESM and CSM operators have been provided GUIs that provide more information on their respective sensors in the ESM and CSM mode. The data along with audio and video of each OWS is recorded and stored for analysis and playback. The GASP mode provides a reconstruction of the entire mission and allows the operator to interact with the display. The IVPB mode provides an audio video replay of the mission. The operators can playback at various speeds, pause and bookmark various entities of interest. The two different playback modes provide the operator with unique and enhanced tools to analyze data post mission. It helps them to further fine-tune their strategy and to suggest further improvements to system. The requirement to meet the audio video recording of the mission is catered to by a recording unit. The Onboard Training Mode provides the operators facility to designate instructor and trainee consoles for providing training onboard during the mission. Along with the onboard training mode, several training sessions have been provided by the CABS team to the command and control operators to train them on the system. OWS has been inducted in two AEW&C systems, at 200 Sqn of the IAF. Close to 1,000 hours of development flight testing had been carried out. Air Force has also carried out extensive evaluation of the system under realistic operational conditions and through simulated exercises at various bases including large-fleet engagement exercises. SATCOM Radome for AEW&C Satellite Communication (SATCOM) is one of the sub-systems of AEW&C system and is mounted on the top of fuselage of EMB145I aircraft. A radome protects the antenna from environmental effects in addition to transmit and receive electromagnetic radiations. This radome has been designed and developed by CABS and manufactured by a private partner. Radome meets MIL-R-7705B specifications. Electro-magnetic (EM) design of the radomes meets Ku band (for SATCOM) frequency 10.7 to 14.5 GHz radiation requirements. The radome is designed to withstand aerodynamic loads with minimum deflection under critical aerodynamic loading conditions. It is qualified for lightning protection as per MIL-STD-1757A and also meets bird strike requirements as per FAR 25.571 (e) (1). The size of SATCOM radome is 2702 mm x 703 mm x 563mm which is, as of now, one of largest GFRP radomes developed indigenously. The weight of the radome is about 20 kg. The radome has an EM transparent region having sandwich structure, and the interfacing area (to the metal base on the aircraft) made of monolithic structure. Aluminium alloy AA6061T6 strips are bonded in a specific pattern on the radome surface for lightning protection. Radome is also protected with special radome paint. GROUND COMPLEMENTS OF AEW&C System Test Integration Rig AEW&C System being a System of Systems poses greater challenges in integration. The integration gets challenging when these systems have to work in tandem to form an integrated system. The complexity increases when the same is to function in an airborne environment where there are constraints in terms of volume, power, cooling etc. The System Test and Integration (STIR) facility ensures a smooth integration and necessary clearances from the stakeholders before being put on the aircraft to reduce both the time and costly flight testing of the systems. This facility is equipped with simulators for checking the system for mechanical, electrical, digital, RF and software integration and providing an integrated environment for tandem working of the system. The Rig also facilitates in terms of carrying out the behavior of the systems under various scenarios that the mission is likely to encounter and caters for the stress testing of the system– especially when testing against 500 to 1000 targets, handling and ascertaining the lag in the systems for real time performances. The systems can be tested against the environments that are encountered in the operational situation ensuring the performances without subjecting resources in the forward areas for testing of the system. Mission Planning and Analysis Station The Mission Planning and Analysis Station (MIPAS) is a critical ground based system which supports pre-and post-mission activities of the AEW&C. The main task of MIPAS, at the pre-mission phase, is to prepare the Mission Parameter Data (MPD) Library to be uploaded to the AEW&C system. The uploaded MPD library serves as the technical and operational online database during the mission. The pre-mission phase outcome, which is the MPD library (a single MPD is for a specific, single mission sortie), consists of Pre Flight Messages (PFM) files and Tactical Mission Data (TMD) files. Each MPD consists of PFM for the subsystems, which include Radar, IFF, Mission Data Processor (MDP), CSM Communication Support Measures (CSM), Electronic Support Measures (ESM), Self-Protection Suite (SPS), Intercept Control Processor (ICP), Mission Recording and Playback (MRP), Operator Work Station (OWS), and Communication PFMs (V/UHF, C Band and SATCOM). TMD consists of Tactical Data Item (TDI), Weather Data, Mission Order, Mode Code Table, TYCO (Type and Configuration) and GRT (General Rule Table). Tactical Data Item include Fixed Points (like Airbases, Navigation aids, Radar sites, Surface to Air Missiles sites etc), Areas (like Defended areas, Danger zones, Flight corridors etc), and Flight Plans of known aircraft. The PFM and TMD files are needed for the initialization and operation of the airborne mission systems in a specific mission scenario. In a mission sortie, AEW&C generates and records various sensor data (like ESM, CSM), voice, video, RT calls, and navigation data. All these recorded data are required to be decoded and analyzed to improve the performance in future missions. For each sortie these recorded data and video recordings of each operator consoles are very huge. These voluminous data needs to be analyzed in short time. During post-mission, MIPAS supports data download, playback, analysis and report generation based on the downloaded data from the AEW&C. Facility to feed simulated data is also available. Ground Exploitation Station The Ground Exploitation Station is a transportable field deployable system, which can receive the information from AEW&C system both through a LOS and Satellite Data Links. The GES can be located in remote locations, thereby enabling the availability of the air situation picture around them in real time. The Ground Exploitation Station (GES) acts as an interface between the AEW&C and the IACCS. The real-time Recognizable Air Situation Picture (RASP) generated onboard AEW&C is transmitted to the GES, which is, interfaced with the IACCS through an interface unit for dissemination of tactical information to the decision makers on the ground. Similarly, the command from the IACCS to the AEW & C is routed through GES. GES enables the officers to see, live, the sensor data collected by the onboard AEW&C sensors. All this visualization happens on ground (in GES)/Mission Control Room (in IACCS room). The Communication between AEW&C and GES can happen in one of the three modes: CBDL Data link; Ku Band Data link; and V/UHF communication system. The communication between GES and IACCS happens through Ethernet link. Once the sensors data is on IACCS network, it provides seamless availability of the information at any place across India. GES, being a modular design, is easy for transportation and deployment. Multiple GES can be operational at the same time and the live sensor data can be monitored at different geographical locations. It comprises of mission system such as, Mission System Controller (MSC), Mission Communication System (MCS), C Band & Ku Band Data Link system and Operator Work Stations (OWS). All these systems are powered through a Diesel Generator (DG) system. As an entity it comprises of the following shelter / trailer based units, namely GES shelter, DG shelter, trailer mounted CBDL outdoor units, trailer mounted KBDL units and 18m VUHF antenna masts. GES facility has been established at CABS as well as at Air Force Station Bhatinda, Air Force station Jodhpur and Air Force Station Ambala. The main components of GES are as follows: GES Operator shelter: - houses all the indoor LRUs of mission system. It has been designed to accommodate four racks (for fitment of LRUs, UPS and batteries) two operator work station consoles, one CCTV console and power distribution panel. Racks are fitted with various mission system LRUs like system controller, base band units, tracking receivers, antenna control unit, radios, high power amplifiers, VAIU etc. C Band Data Link Trailer: - is fitted with a 1.8 meter dish antenna; with two feed (Main feed & Acquisition Aid Antenna). The antenna is fitted on a scissors lift; the scissors lift aids in the operation of the antenna at an elevated level. The CBDL trailer also houses a drive control unit, a RF system; a dehydrator and a scissors lift motor. Ku Band Data link trailer: - is fitted with a 2.4 meter dish antenna; with its offset feed. The KBDL trailer houses a RF system consisting of Block Up Converter (BUC), Low Noise Block Down Converter (LNBC), and Electronic Compass. Four hydraulic jacks are provided for the trailers, which aids in meeting pointing accuracy of ground KBDL antenna towards satellite. VUHF Masts two 18 meter masts are fitted near the shelter. VUHF antennas are fitted on top of these two masts, which help in attaining maximum range for communication. These are pneumatic masts which can be erected using air compressors. Operator Training Station Operator Training Station (OTS) is a ground-based system for training the operators in a realistic, simulated environment for providing tactical training, command & control and battle management by simulating the behavior of different airborne sensors under dynamically varying scenarios. It aids in providing hands on training to fighter controllers and judging the operational competence of the squadrons. It not only trains the operators in simulated scenarios comprising of Computer Generated Forces (CGF) but also by recreating previous mission sortie’s recorded large scale integrated exercise scenarios and thus providing exponential benefits. The facility enables enormous cost saving of training in flights of high value asset mission platforms such as AEW&C, thereby conserving precious flying missions. This facility has been extensively used by the Fighter controllers/ Mission Operators for training under different battlefield scenarios on ground. The OTS has capability to train either five Mission operators with five instructors controlling each one of them or one Instructor, training nine mission operators simultaneously. It also has capability of simulated pilot sitting on IOS controlling its own simulated entities. OTS basically comprises of the Instructor Operator Station (IOS), Trainee Operator Station (TOS) and Server Rack Automated Test Equipment The maintenance philosophy of the AEW&C system is maintenance at three levels, namely, I (Intermediate), O (Operational) and D (Depot). ‘O’ level maintenance tasks are performed at the operational base mostly in-situ for all the systems. CABS has designed & developed Automated Test Equipment for testing of Mission System LRUs towards I level maintenance of AEW&C. The purpose of the ATE is to provide the simulating input to the LRUs and measuring the response based on which decision can be made, whether LRU can be declared as OK or not. The testing of the faulty LRUs off loaded from the Mission System is also done in ATE. It also carries out tests on spare LRUs to the required level of confidence prior to mounting into the Mission System. The ATE comprises modular and standard commercially-off-the-shelf test equipment interconnected through PXI/PXIe/GPIB bus and also through a fully managed Ethernet Switch. Excitation and measurement is done by the test equipment in the ATE through ITA. The ATE software is built on industry standard platform- NI LabVIEW and NI Test Stand. NI Test Stand is ready-to-run test management software that is designed to develop automated test and validation. In addition, test sequences that integrate code modules written in any test programming language can also be developed. Sequences also specify execution flow, reporting, database logging, and connectivity to other enterprise systems. Mission Software Support Facility The Mission Software Support Facility (MSSF) is one of the Ground Segment of AEW&C & is used to provide software maintenance and configuration management of the AEW&C system. The AEW&C system software is maintained at CSCI (Computer Software Configuration Item) level in the MSSF facility. The MSSF is used as a secure and centralized repository to store the software work-products of AEW&C sub-systems. The advantage of such repository is to make available all the software for AEW&C at a single place over the life time of the system. A Software Configuration Management server is used to store the software work products. PLM Implementation for AEW&C PLM as conceptualized for the AEW&C programme has been implemented as a new way to think about product information towards execution of DRDO programmes within the time & cost constraints meeting all the user specified requirements. The design, development, integration & certification of the AEW&C system involves several partners geographically distributed. A need was felt to pull together interrelated and interdependent information and disparate applications into coherent processes and consolidate all the AEW&C Programme information & processes into a common system. It was felt necessary to provide a collaborative environment through deployment of state-of-the-art technologies both in hardware & software for managing the complex AEW&C Programme environment thereby enabling project teams to use tools, processes & methods that are unified under a heterogeneous environment. The PLM solution proposed was about taking a ‘Systems Approach’ with respect to the information generated to support faster & more informed decision-making throughout the programme lifecycle. The system so implemented have the ability to capture data in a holistic manner with respect to the technology, processes and people across the organization as well as the work-centres working for the AEW&C development. The software enabled an organized process for creation, updating, storage backup, archival, access control and retrieval of all data related with the AEW&C product & programme/ project. It also ensured the management and control of configuration for design data as well as to control the flow of work within and across work groups & workcentres in respect of product/project data of the organization. It enabled in controlling processes and ensuring regulatory compliances. The document management and control functionalities built in to support all documentations of the organization including various types of design data such as drawings, 3D models, analysis, software outputs, in-house software, text documents etc. Data validation procedures ensured consistency & correctness of data. Thus, the PLM solution provided a complete enterprise solution for all its present and future endeavors in the development of the AEW&C Programme. Netra 2.0 With the induction of the indigenous AEW&C into the Indian Air Force, DRDO move forward to the next generation system development for the Services, for which preliminary technology initiatives are already well underway. In Netra 2.0 project Defense Research Development Organization (DRDO) will develop six Airborne Early Warning and Control System (AWACS) aircraft for the Indian Air Force. Six airbus 320 will be acquired from, Air India, for the project. To modify the aircrafts for mounting sensors and AESA radar DRDO will send the aircraft to its European manufacturer. Netra 2.0 will be a scaled-up variant of the Netra Mk1 AEW&C. Netra Mk2 will use GaN based TRMs, and will have more than twice the range of Netra Mk1. A320 is a bigger platform than ERJ 145, so that DRDO can use bigger radar packed with more transmit receive modules(TRM). A320s bigger engines will meet additional power requirement of the new radar. According to CABS all six Netra Mk2 will be handed over to IAF within 2028. Netra Mk2 will cover more than 240° what mk1 capable of, Netra mk2 will cover 300° (according to some reports similar to mk1 ie; 240). The radar configuration will be similar to Netra Mk1, Two active antenna array unit (AAAU) assembled back-to-back and mounted on top of the fuselage. Netra Mk2 can also detect low observable platforms from long distances. Netra Mk2 can perform better in intense EW environment. Netra Mk2 may have synthetic aperture radar for Maritime and Ground Surveillance. The Maritime surveillance Radar will make mk2 capable of Detecting targets at sea and make it swing-role capable AEW&C. A330 based 360 degree AEW&C In 2015, the Indian MoD cleared an Rs 5113 crore program to build an Airbus A330 based AWACS system. While work on the dorsal radome has made progress at the DRDO’s Centre for Airborne Systems (CABS) in Bengaluru, a contract for the aircraft platforms has remained elusive five years after the DRDO was cleared to begin procurement procedures. The plan was to convert the aircraft and deliver them to the forces by 2024-25. It is not clear if Netra 2.0 supplants earlier plans by the DRDO to deliver an Airbus A330 based AWACS system, though the two systems are significantly different in capability and scope. A330 based AEW&C planned to provide 360-degree coverage deep inside the enemy territory during missions. The new AWACS would be equipped with advanced sensors and avionics, making them much superior surveillance platforms in the air. MORE PICTUERS

Srivatsa RV

2/24/2023 11:11:39 pm

This is a complete copy paste from the DRDO Monograph , verbatim, information is impressive. But it's not worded by you.

Reply

Leave a Reply. |

AuthorPalash Choudhari Archives

June 2021

Categories

All

|

RSS Feed

RSS Feed