|

Propulsion in a broad sense is the act of changing the motion of a body. Propulsion mechanisms provide a force that moves bodies that are initially at rest, changes a velocity, or overcomes retarding forces when a body is propelled through a medium. Jet propulsion is a means of locomotion whereby a reaction force is imparted to a device by the momentum of ejected matter. Rocket propulsion is a class of jet propulsion that produces thrust by ejecting stored matter, called the propellant. Duct propulsion is a class of jet propulsion and includes turbojets and ramjets; these engines are also commonly called air-breathing engines. Duct propulsion devices utilize mostly the surrounding medium as the "working fluid", together with some stored fuel. The energy source most useful to rocket propulsion is chemical combustion. Energy can also be supplied by solar radiation and, in the past, also by nuclear reaction. Accordingly, the various propulsion devices can be divided into

Radiation energy can originate from sources other than the sun, and theoretically can cover the transmission of energy by microwave and laser beams, electromagnetic waves, and electrons, protons, and other particle beams from a transmitter to a flying receiver. Nuclear energy is associated with the transformations of atomic particles within the nucleus of atoms and can be of several types, namely, fission, fusion, and decay of radioactive species. Other energy sources, both internal (in the vehicle) and external, can be considered. The energy form found in the output of a rocket is largely the kinetic energy of the ejected matter; thus the rocket converts the input from the energy source into this form. The ejected mass can be in a solid, liquid, or gaseous state. Often a combination of two or more of these is ejected. At very high temperatures it can also be a plasma, which is an electrically activated gas. DUCT JET PROPULSION This class, also called air-breathing engines, comprises devices which have a duct to confine the flow of air. They use oxygen from the air to burn fuel stored in the flight vehicle. The class includes turbojets, turbofans, ramjets, and pulsejets. ROCKET PROPULSION Rocket propulsion systems can be classified according to the type of energy source

The basic function

The type of vehicle

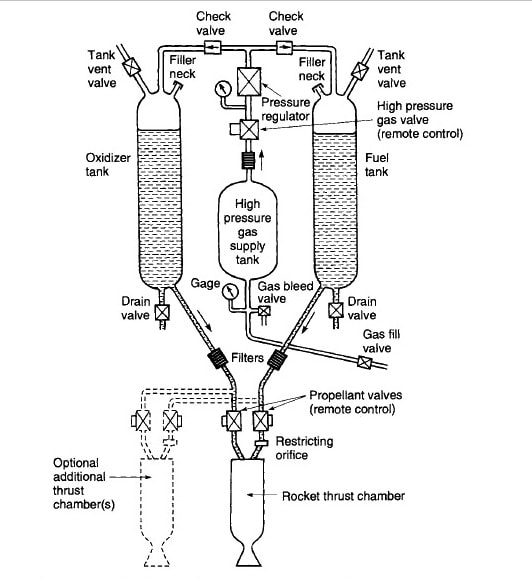

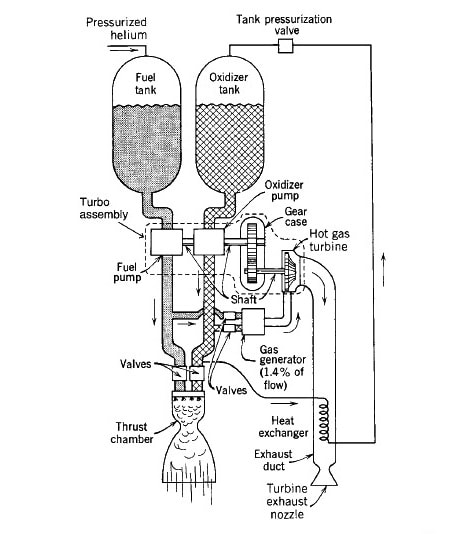

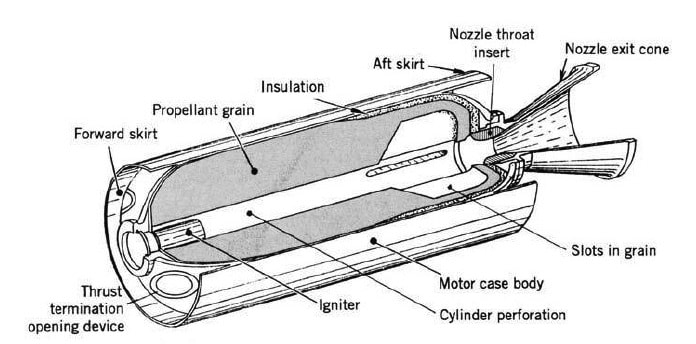

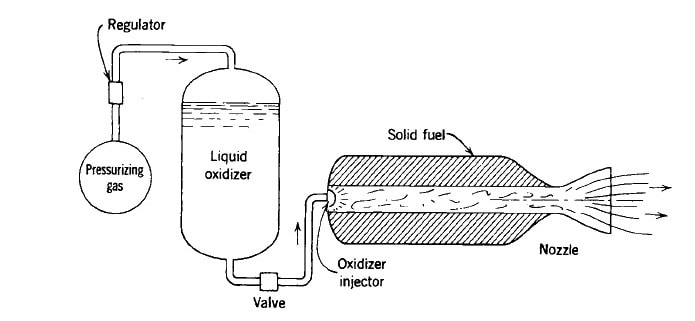

Another way is to Classify by the method of producing thrust. A thermodynamic Expansion of a gas is used in the majority of practical rocket propulsion concepts. The internal energy of the gas is converted into the kinetic energy of the exhaust flow and the thrust is produced by the gas pressure on the surfaces exposed to the gas, This same thermo-dynamic theory and the same generic equipment (nozzle) is used for jet propulsion, rocket propulsion, nuclear propulsion, laser propulsion, solar-thermal propulsion, and some types of electrical propulsion. Totally different methods of producing thrust are used in other types of electric propulsion or by using a pendulum in a gravity gradient. Chemical Rocket Propulsion The energy from a high-pressure combustion reaction of propellant chemicals, usually a fuel and an oxidizing chemical, permits the heating of reaction product gases to very high temperatures (2500 to 4100°C or 4500 to 7400°F). These gases subsequently are expanded in a nozzle and accelerated to high velocities (1800 to 4300 m/sec or 5900 to 14,100 ft/sec). Since these gas temperatures are about twice the melting point of steel, it is necessary to cool or insulate all the surfaces that are exposed to the hot gases. According to the physical state of the propellant, there are several different classes of chemical rocket propulsion devices. Liquid propellant rocket engines use liquid propellants that are fed under pressure from tanks into a thrust chamber. A typical pressure-fed liquid propellant Rocket engine system is schematically shown in Fig The liquid bipropellant consists of a liquid oxidizer (e.g., liquid oxygen) and a liquid fuel (e.g., kerosene). A monopropellant is a single liquid that contains both oxidizing and fuel species; it decomposes into hot gas when properly catalyzed. A large turbopump-fed liquid propellant rocket engine is shown in this Fig Gas pressure feed systems are used mostly on low thrust, low total energy propulsion systems, such as those used for attitude control of flying vehicles, often with more than one thrust chamber per engine. Pump-fed liquid rocket systems are used typically in applications with larger amounts of propellants and higher thrusts, such as in space launch vehicles. In the thrust chamber the propellants react to form hot gases, which in turn are accelerated and ejected at a high velocity through a supersonic nozzle, thereby imparting momentum to the vehicle. A nozzle has a converging section, a constriction or throat, and a conical or bell-shaped diverging section Gas pressure feed systems are used mostly on low thrust, low total energy propulsion systems, such as those used for attitude control of flying vehicles, often with more than one thrust chamber per engine. Pump-fed liquid rocket systems are used typically in applications with larger amounts of propellants and higher thrusts, such as in space launch vehicles. Some liquid rocket engines permit repetitive operation and can be started and shut off at will. If the thrust chamber is provided with adequate cooling capacity, it is possible to run liquid rockets for periods exceeding 1 hour, dependent only on the propellant supply. A liquid rocket propulsion system requires several precision valves and a complex feed mechanism which includes propellant pumps, turbines, or a propellant-pressurizing device, and a relatively intricate combustion or thrust chamber. In solid propellant rocket motors the propellant to be burned is contained within the combustion chamber or case. The solid propellant charge is called the grain and it contains all the chemical elements for complete burning. Once ignited, it usually burns smoothly at a predetermined rate on all the exposed internal surfaces of the grain. Initial burning takes place at the internal surfaces of the cylinder perforation and the four slots. The internal cavity grows as propellant is burned and consumed. The resulting hot gas flows through the supersonic nozzle to impart thrust. Once ignited, the motor combustion proceeds in an orderly manner until essentially all the propellant has been consumed. There are no feed systems or valves Gaseous propellant rocket engines use a stored high-pressure gas, such as air, nitrogen, or helium, as their working fluid or propellant. The stored gas requires relatively heavy tanks. These cold gas engines have been used on many early space vehicles as attitude control systems and some are still used today. Heating the gas by electrical energy or by combustion of certain monopropellants improves the performance and this has often been called warm gas propellant rocket propulsion. Hybrid propellant rocket propulsion systems use both a liquid and a solid propellant. For example, if a liquid oxidizing agent is injected into a combustion chamber filled with solid carbonaceous fuel grain, the chemical reaction produces hot combustion gases. There are also chemical rocket propulsion combination systems that have both solid and liquid propellants. One example is a pressurized liquid propellant system that uses a solid propellant to generate hot gases for tank pressurization; flexible diaphragms are necessary to separate the hot gas and the reactive liquid propellant in the tank.

Leave a Reply. |

AuthorANOOP MADHAVAN Archives

August 2022

Categories |

RSS Feed

RSS Feed